Ex-pert Electrical Perspective

A Dynamic academic elaboration on the Art & Science of Hazardous Area Protection

- 1. About

- 1.1 About Ex

- 2. Author

- 3. Introduction to Ex

- 4. Protection Techniques

- 5. Terminology

- 6. Cable Glands

- 7. IEC: Hazardous Area Standards

- 7.1 …more about IEC

- 8. Ex-Art

- 8.1 Ex Art -variations

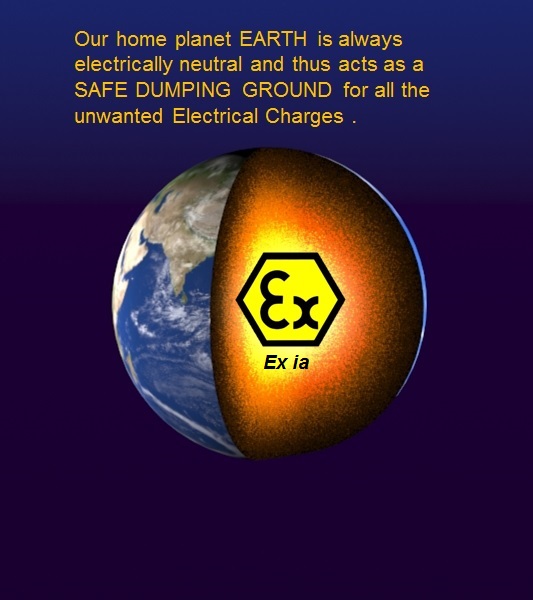

- 8.2 ELECTROSTATIC & Ex

- 9.Reading an Ex Label

- 91. Presentations >>

- 92.Class-Zone-Division

- 93. Non-Electrical side

- 94. Inspection & Maintenance

- 95. expertdesk

- 95.1 expertdesk II

- 95.2 expertdesk III

- 96. Schematic approach to classification of hazardous areas

To Use… or NOT to use.. Conduits or Cables

Conduit or Cable for Ex d or Ex de Enclosures

The term ‘Conduits’ refer to the use of Ex-certified metallic pipes to house the insulated electrical wires for transfer of electrical current.

To use conduits or cables in a certain hazardous location depends mainly on the specifications governing the whole situation and scenario. The rule of thumb is : If the specs being followed are NEC 500 then conduits .. if the specifications belong to the NEC 505 OR IEC 60079 family of documents then CABLES will be the choice.

In principle there are three methods of providing electrical connections:

- Cables system with indirect cable entry, through separate Connection Boxes

- Cables system with direct entry

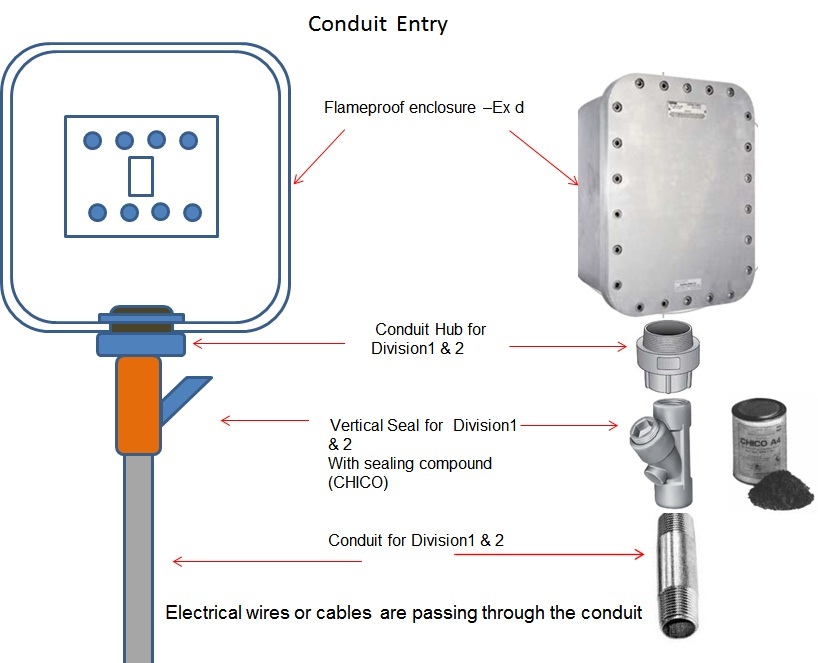

- Conduit Systems

Cables Systems with indirect and direct entries are specified in IEC complied systems and Conduit systems are only permitted in accordance with NEC 500.

Cable Systems:

Cable systems are mainly used in countries following IEC code. For this, high-quality cables, armored or unarmored, are laid uncovered. It is only in areas in which mechanical damage could be expected that they are laid in conduits that are open at both ends. (The ends of the conduits may require sealing for the purpose of VERMIN Proofing)

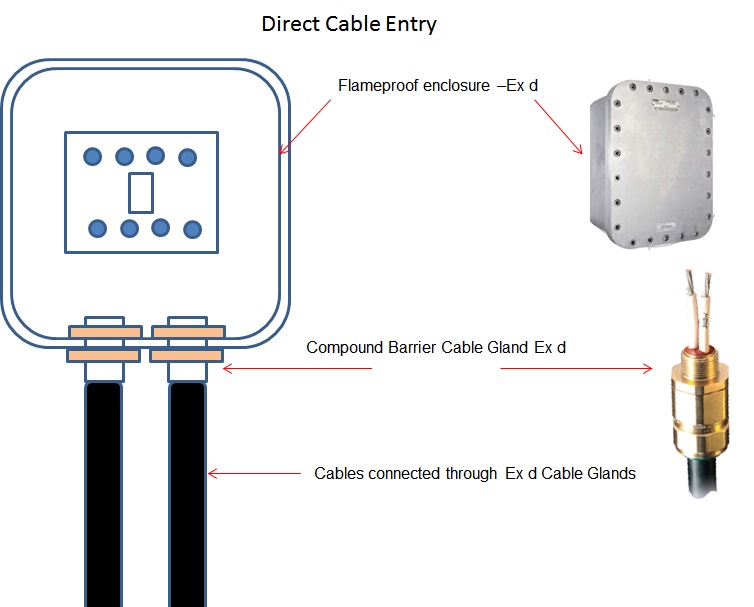

Method No.1

Cable is installed through Ex e / Exed Metallic or non-metallic, certified cable glands

Method No.2

Method No.3 (NEC Specified )

Merits & Demerits of the three systems of connecting an Ex d or Ex de enclosure to an electrical network.

Conduit System:

- It is strong & robust

- Fire-proof (all metal)

- High cost of installation

- Time consuming installation

- Possibility of corrosion

- High cost of changes/augmentations (Rigid design)

- INSTALLER is responsible for Ex Integrity (Flameproof) because all installation is carried out on site.

Direct Cable Entry

- Flexible & thus fast installation

- Flexible design for changes

- Low cost of maintenance

- Cables require protection from damages

- INSTALLER is responsible for Ex Integrity (Flameproof) because all installation is carried out on site.

Indirect Cable Entry

- Flexible & thus fast installation

- Flexible design for changes

- Low cost for maintenance

- Cables require protection from damages

- Manufacturer is responsible for Ex Integrity (Flameproof) .Cables are just connected into the Ex e enclosure at site

Some Important Remarks from IEC 60079-14 (Edition 6)

No. 1

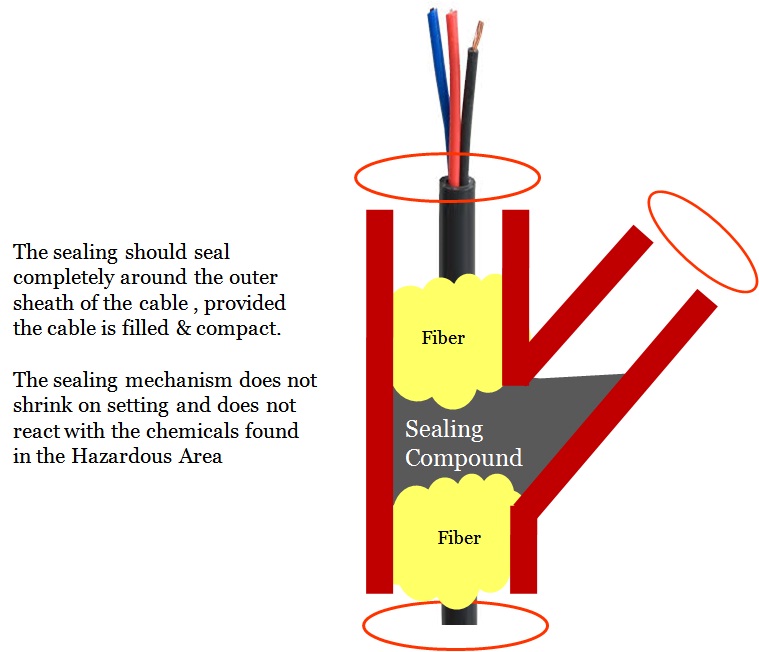

If required to maintain the appropriate degree of ingress protection (e.g. IP54) of the enclosure, the conduit shall be provided with a conduit sealing device adjacent to the enclosure.

The conduit shall be wrench tight at all of the threaded connections.

No.2

Additional remarks about conduits

Group II

Rigid conduits used in closed wiring systems shall be heavy wall threaded metallic conduits or fiberglass RTRC conduits.

NOTE 1 A closed wiring system is described as a system where conduits connect directly from one enclosure to another enclosure.

Where a conduit is entering Ex “d” equipment, an Ex “d” conduit seal shall be installed within

50 mm of the Ex “d” equipment.

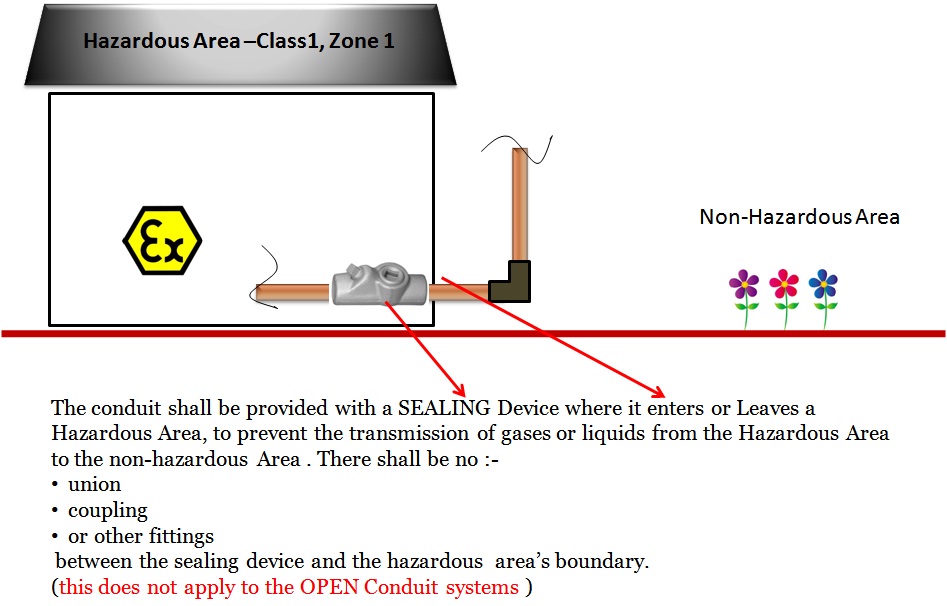

A conduit seal shall be installed where a conduit passes from a hazardous area

- requiring EPL Ga to an area requiring either EPL Gb or Gc as near as practicable to the

EPL Ga equipment; and - to a non-hazardous area with the conduit seal installed in the non-hazardous area.

NOTE 2 This requirement does not imply that the conduit seal must be an Ex “d” conduit seal.

Where flexible connections are necessary, for example to address vibration or movement, short lengths of heavy-duty liquid tight flexible metallic conduit or fiberglass RTRC conduit may be used.

In the absence of IEC standards for conduits, national standards or other standards should be followed.

Group III

Rigid conduits used in closed wiring systems shall be heavy wall threaded metallic conduits or fiberglass RTRC conduits.

NOTE A closed wiring system is described as a system where conduits connect directly from one enclosure to another enclosure.

Where flexible connections are necessary, for example to address vibration or movement, short lengths of heavy-duty liquid tight flexible metallic conduit or fiberglass RTRC conduit may be used.

In areas of low probability of mechanical damage, rigid plastic conduits and fittings meeting the test conditions of IEC 60079-0 may be used. Joints shall be securely made for example solvent welded.

The conduit system shall be impervious to dust.

Entry by conduit shall be either by screwing into threaded holes or by locking in plain holes

- in the wall of the enclosure; or

- in an adaptor plate designed to be fitted in or on the walls of the enclosure; or

- into a suitable box, integral with or attached to the wall of the enclosure

The OPEN CONDUIT SYSTEM

Conduits can be used for Mechanical Protection ONLY. Cables are drawn through the conduits and the ends of the conduits remain open . However some sort of sealing is definitely required to prevent the :-

- Ingress of VERMIN inside the conduit

- Prevent the flow of rain water though the conduits

This system is in contrast to the STANDARD SYSTEM of Conduit Installation (As per NEC 500)

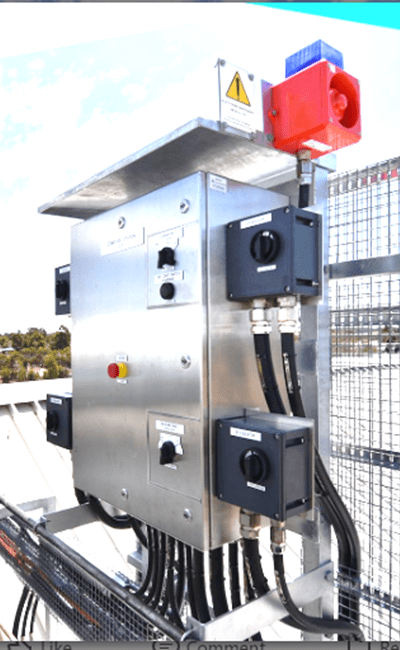

(Example : The cables are connected through cable glands and protected by open conduits )

Another example of OPEN CONDUITS . (Control station is connected through non-metallic Cable Gland and connecting cable is protected through a open conduit. )

Information

This entry was posted on October 28, 2012 by verdah in Uncategorized and tagged conduit, electrical, insulation, metallic, pipes, Seal, wires.Shortlink

https://wp.me/p8t0O-jNavigation